Kingspan Kooltherm K17 Insulated Plasterboard

From $1739.32

From $ 62.86 p/m2 inc. GST

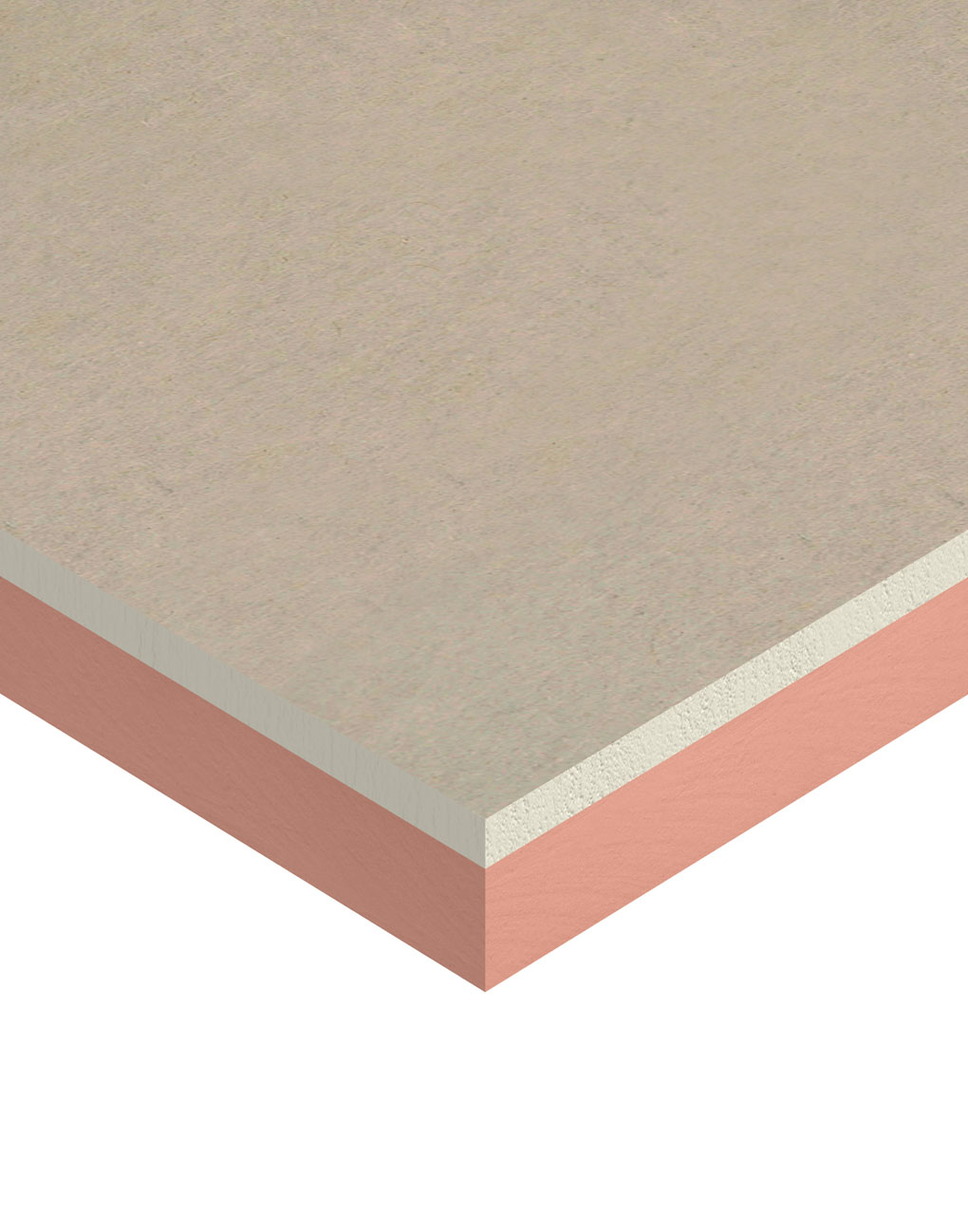

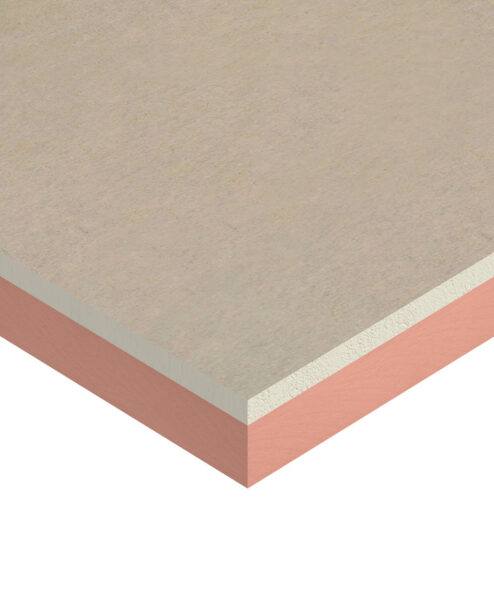

Kingspan Kooltherm® K17 Insulated Plasterboard is suitable for a wide range of commercial projects. K17 Insulation has a fibre-free, closed cell insulation core with a gypsum plasterboard face.

🚚 Made to Order – Allow 10 to 14 Days Delivery

Kingspan Kooltherm K17 – Insulated Plasterboard

Kingspan Kooltherm K17 Insulated Plasterboard is a fibre-free rigid thermoset, closed cell phenolic insulation, sandwiched between a front facing of tapered edge gypsum based plasterboard, and a reverse tissue based facing adhesively bonded to the insulation core during manufacture. Kingspan is renowned among plasterboard suppliers for it’s superbly insulated thermal plasterboard sheets. Alternative lining boards, such as fibre cement sheets, can also be bonded to the insulation core to create customised finishes and facings in our Kingspan Kooltherm K17 + Insulated Lining Board range.K17 Plasterboard Features

- Australian Made

- CodeMark certified for NCC compliance

- NCC and AS/NZS 4859.1:2018 compliant

- Global GreenTag GreenRate-certified

- Also used for residential & modular construction

- Fire-free, closed cell insulation core

- 3-in-1 insulation, dry lining and vapour control

Product Description and Durability

If correctly applied, Kingspan Kooltherm® products can be expected to have a long life of service. Their durability depends on the supporting structure and the conditions of its use. Kingspan Kooltherm® products are warranted for a period of 10 years for both residential and commercial installations. This is subject to the terms of the complete Kingspan Kooltherm® warranty document. Kingspan Kooltherm K17 Insulated Plasterboard has a gypsum plasterboard face. It should, therefore, not be used to isolate dampness nor be used in continuously damp or humid conditions. This product can be applied utilising a variety of traditional or modern dry-lining techniques, to dry and structurally sound walls. These include the construction adhesive bonding method. The particular system employed will depend on the construction or design of the wall to which Kingspan Kooltherm K17 Insulated Plasterboard is to be fixed. If an acceptable adhesive bond cannot be achieved due to the wall surface, consideration should be given to a mechanically fixed option. The tapered edge to the plasterboard enables a flat seamless surface equal to traditional plaster finishes after the correct jointing procedures as per plasterboard manufacturer’s recommendation have been completed.Construction Adhesive Bonding

This method is for application to brick, block or concrete masonry cavity walls which are free from moisture penetration.- Ensure that the wall surface to be bonded to is free from oil, grease, paint, release agent, or any contaminate that may affect the bond of the adhesive to the wall.

- Gun apply a continuous blob of construction adhesive around perimeter wall and ceiling junctions, and around any openings, such as windows and doors, in order to provide a seal.

- Gun apply blobs of construction adhesive to the wall or the back of the board approximately 25 mm in diameter (single squeeze), at 300 mm centres in both directions or to specific adhesive manufacturer’s instructions. Ensure that the blobs adjacent to a board joint are approximately 25 mm in from the edge to avoid bridging the joint.

- Tap the board back firmly using a straightedge, ensuring that the vertical edge is plumb.

- Continue dry lining in the same manner.

- Provide temporary mechanical support to the Kingspan Kooltherm K17 Insulated Plasterboard for at least 24 hours.

- Mechanical fixings are recommended to complement the adhesive bond. Apply 2 per board after the adhesive has set, positioned 15 mm in from the board edge and at mid height with a nominal 25 mm embedment into the wall. (Refer to fixing manufacturer instructions for more information).

- It is recommended that mechanical fixings are positioned in the tapered edge of the boards so that they are covered when the board is finished, (e.g. joints taped and skim coating) at mid height. Boards should be fitted tight to the ceiling/joists

Handling, Storage and Installation of Insulation Panels

The packaging of Kingspan Kooltherm® should not be considered adequate for long term outdoor protection. Ideally boards should be stored inside a building. If, however, outdoor storage cannot be avoided then the boards should be stacked clear of the ground and covered with an opaque polythene sheet or weatherproof tarpaulin. Boards that have been allowed to get wet should not be used. The insulation core is resistant to short–term contact with petrol and with most dilute acids, alkalis and mineral oils. However, it is recommended that any spills be cleaned off fully before the boards are installed. Ensure that safe methods of cleaning are used, as recommended by suppliers of the spilt liquid. The insulation core is not resistant to some solvent-based adhesive systems, particularly those containing methyl ethyl ketone. Adhesives containing such solvents should not be used in association with this product. Damaged boards or boards that have been in contact with harsh solvents or acids should not be used. Kingspan panels are chemically inert and safe to use. Cutting should be carried out either by using a fine toothed saw, or by using a sharp knife to cut through the insulation and paper backing of the plasterboard, then snapping the board face down over a straight edge and cutting the paper facing of the plasterboard on the other side. Ensure accurate trimming to achieve close butting joints and continuity of insulation.Choose Your Date

You can choose your preferred delivery or pickup date at the online checkout. We will contact you the same business date to confirm the delivery or pickup arrangements.

Fast Deliveries

Standard orders are delivered within 1-2 business days in metro areas and 1-3 days in regional areas. Some products have a longer lead time as indicated on the product page.

Delivery Pricing

Get your insulation delivered from just $99 in Melbourne, Sydney, Brisbane, Adelaide and Canberra. For regional and island delivery pricing please click here or contact us.

Leave or Sign

If you won't be home on the day of delivery then please leave a note at checkout to let us know where your order can be left. Please choose a dry area out of the rain.

Returns

Returns must be made within 30 days of purchase and will incur a 15% - 30% restocking fee. Some custom made products cannot be returned. For further information, please read our Returns Policy.

Warehouse Pickups

Each brand has a different pickup location. Please contact us for the nearest pickup location in your state. Standard orders are ready for collection within 1-2 days.

How Ordering Works

Regional Delivery Prices

The delivery price will be calculated at the checkout based on your postcode. For a custom delivery quote please contact us.

Pricewise Insulation Returns Policy

Leftover products may be returned to Pricewise Insulation if they meet the below requirements:

- Items must be returned within 30 days of ordering.

- Insulation products must be in their original packaging and condition. We reserve the right not to refund wet or damaged products.

- A 15% restocking fee will apply for glasswool, polyester and rockwool products.

- A 30% restocking fee will apply for foam and rigid insulation products.

Please also note the following:

- We cannot guarantee returns or refunds for custom made products.

- Some manufacturers do not allow returns in certain states. This will be outlined on the product page itself.

You may return the insulation to the warehouse which it was dispatched from or pay for a courier to collect it from your home or building site. Please give our team a call on 1300 729 639 to make arrangements.

If you are not sure how much insulation you require for your project, our team is happy to assist. Please send an email to sales@pricewise.com.au.

| Product | Thickness | Length (mm) | Width (mm) | Area per pack (m²) | Boards |

| K17 35 | 25 | 2400 | 1200 | 34.56 | 12 |

| K17 40 | 30 | 2400 | 1200 | 28.8 | 10 |

| K17 50 | 40 | 2400 | 1200 | 23.04 | 8 |

| K17 60 | 50 | 2400 | 1200 | 17.28 | 6 |

| K17 70 | 60 | 2400 | 1200 | 14.4 | 5 |

| K17 80 | 70 | 2400 | 1200 | 11.52 | 4 |

| K17 90 | 80 | 2400 | 1200 | 11.52 | 4 |

| K17 100 | 90 | 2400 | 1200 | 8.64 | 3 |

| K17 110 | 100 | 2400 | 1200 | 8.64 | 3 |