Foilboard Floor Saddles

From $33.09

From $ 33.09

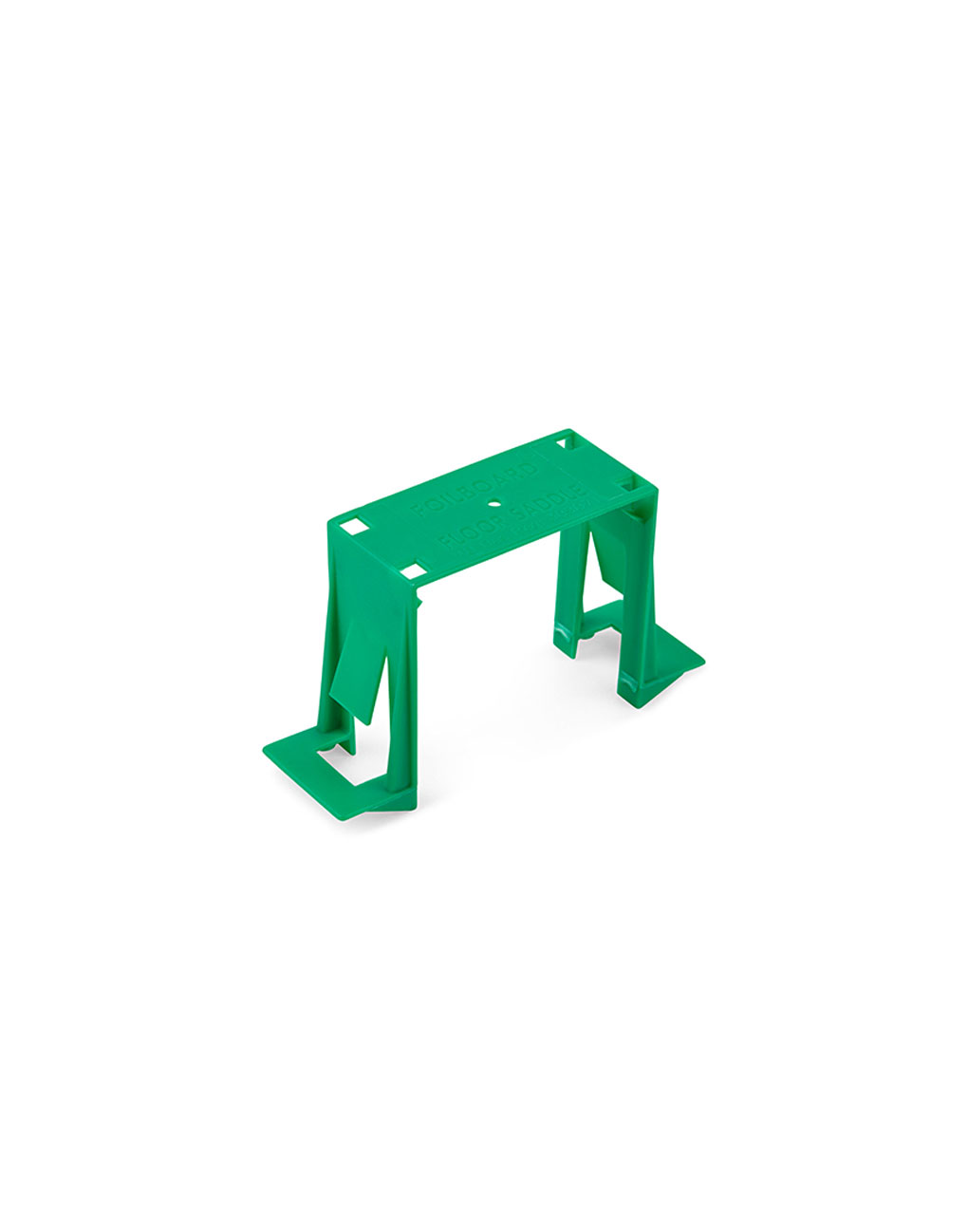

Foilboard Floor Saddles are used when installing Foilboard before the flooring is laid. Fixed under the floor joists, Foilboard Floor Saddles greatly improve the thermal performance of the floor and make underfloor insulating easy.

Foilboard Floor Saddles

Foilboard Floor Saddles are used when installing Foilboard before the flooring is laid. Fixed under the floor joists, Foilboard Floor Saddles greatly improve the thermal performance of the floor and make underfloor joist insulation easy. Simply place the saddle over the floor joist and fasten with a nail or staple. Then slip the Foilboard® between the floor joists and clip into place.

Foilboard Floor Saddles for Foil Underfloor insulation

Foilboard Australia Pty Ltd manufactures a range of fixing accessories tailored to suit many construction applications. These Foilboard timber fasteners ensure that the material will be installed correctly and maintain its thermal performance for the life of the application. Whether it is for timber or steel frame construction, underfloor applications and even commercial systems, Foilboard® has the right fixings to suit all applications.

Installation suggestions for Underfloor Foilboard

Insulation panel and Floor Saddles is best done after joists are fixed to bearers and before yellow tongue or strip flooring is laid down. It is recommended that for best-fit plumbing rough in and all other services under floor are complete. Foilboard Insulation Panel is lightweight, easy and safe to handle. It may be easily cut to size with a long snap blade knife. Off-cuts can be taped and re-used.

Space Foilboard Floor Saddles on top of floor joists at approximately 600mm centres. Saddles should be spaced 200mm from end of sheet. At double joists simply cut the Foilboard Floor Saddles in half and fasten with a nail. Push Floor Saddles down so that the specially designed teeth can grip the joist. Cut Foilboard under insulation panel to size to fit in-between joists. Place sheet between joists, resting on the lip of the Floor Saddles. Gently apply pressure to the Foilboard Insulation Panel until it clicks into place with our patented lock-in flap design. This will prevent wind and vermin from unsettling the sheet from underneath. For a perfect job sheets should be taped where they join. Tape or silicone gaps and holes to prevent air infiltration that lowers the ‘R’ value.

Method of Calculating Quantities of Foilboard

- Measure Floor or Wall area.

- Add 5% to area to allow for cutting and waste, deduct window and door openings.

- If using 2.44m sheets divide the area by 2.93 to give the number of sheets required.

- If using 2.70m sheets divide the area by 3.24 to give the number of sheets required.

- Round up to the next full sheet.

- Floor saddles should be on joists at approx 600mm centres and spaced at 200mm from sheet ends.

- For retro-fits Foilboard should span across the underside of joists and between bearers using three Foilboard fasteners per joist. Joins do not need to be made on a joist and you should tape all joins.

- Generally 1 bag of saddles is required for every 45-50m2 and 1 Role of Green Tape will be required for every 100m2. For retro-fits you will generally require 1 bag of Foilboard Fasteners and 1 roll of Green Tape for every 15-20 sheets, for Aluminium tape you will require one roll for every 10-12 sheets approx. Flexifastners should be used for all sheets 25mm or thicker and you will require 1 bag of 200 fastners for every 15-20 sheets. Or for sheets over 25mm in thickness you can order the plastic plates and supply your own fixing nails or screws. Spacers for brick work you will require 8-10 spacers per m2

Residential Wall

For example, an area of 130m2 (residential wall – timber/steel frame excluding windows) will require;

- 45 sheets of Foilboard® Insulation Panel (2440mm x 1200mm, 2.93m2 per sheet)

- 3 bags of fasteners (Standard or Ultra)

- 3 Rolls of Green UV PVC Tape

Underfloor Area

For traditional underfloor applications using timber joists at 450mm centres (130m2);

- 45 sheets of Foilboard® Insulation Panel (2440mm x 1200mm, 2.93m2 per sheet)

- 3 bags of Foilboard® Floor Saddles

- 3 Rolls of Green UV PVC Tape

Choose Your Date

You can choose your preferred delivery or pickup date at the online checkout. We will contact you the same business date to confirm the delivery or pickup arrangements.

Fast Deliveries

Standard orders are delivered within 1-2 business days in metro areas and 1-3 days in regional areas. Some products have a longer lead time as indicated on the product page.

Delivery Pricing

Get your insulation delivered from just $99 in Melbourne, Sydney, Brisbane, Adelaide and Canberra. For regional and island delivery pricing please click here or contact us.

Leave or Sign

If you won't be home on the day of delivery then please leave a note at checkout to let us know where your order can be left. Please choose a dry area out of the rain.

Returns

Returns must be made within 30 days of purchase and will incur a 15% - 30% restocking fee. Some custom made products cannot be returned. For further information, please read our Returns Policy.

Warehouse Pickups

Each brand has a different pickup location. Please contact us for the nearest pickup location in your state. Standard orders are ready for collection within 1-2 days.

How Ordering Works

Regional Delivery Prices

The delivery price will be calculated at the checkout based on your postcode. For a custom delivery quote please contact us.

Pricewise Insulation Returns Policy

Leftover products may be returned to Pricewise Insulation if they meet the below requirements:

- Items must be returned within 30 days of ordering.

- Insulation products must be in their original packaging and condition. We reserve the right not to refund wet or damaged products.

- A 15% restocking fee will apply for glasswool, polyester and rockwool products.

- A 30% restocking fee will apply for foam and rigid insulation products.

Please also note the following:

- We cannot guarantee returns or refunds for custom made products.

- Some manufacturers do not allow returns in certain states. This will be outlined on the product page itself.

You may return the insulation to the warehouse which it was dispatched from or pay for a courier to collect it from your home or building site. Please give our team a call on 1300 729 639 to make arrangements.

If you are not sure how much insulation you require for your project, our team is happy to assist. Please send an email to sales@pricewise.com.au.