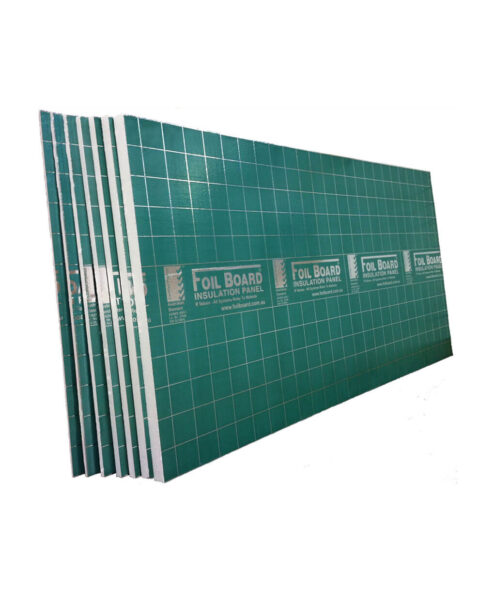

Rigid Insulation Board

Maintaining a comfortable temperature inside buildings is paramount in Australia’s climate. Year-round, rigid insulation boards offer a sustainable solution that can help you save on energy bills. Whether you’re a homeowner or a building professional, we can help you choose the right rigid board insulation for your project.

What are Rigid Insulation Boards?

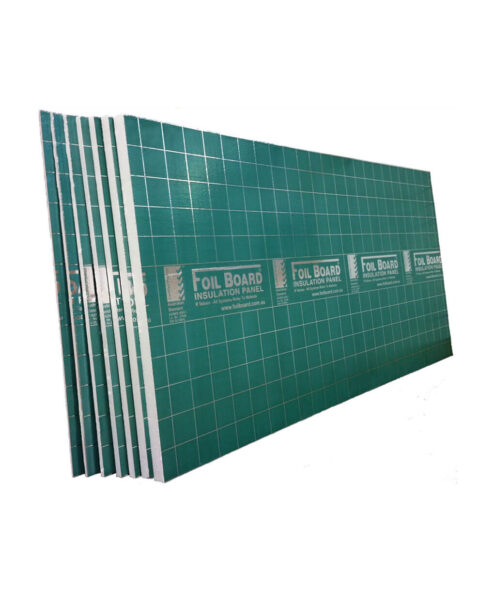

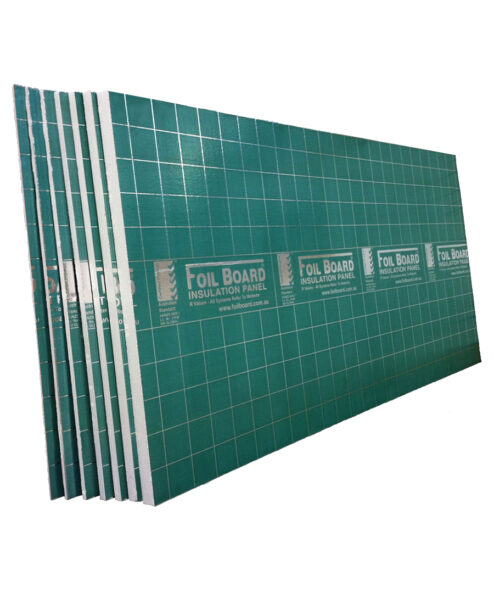

A versatile building material, rigid insulation boards (also known as rigid insulation panels and rigid foam board insulation) is a firm panel used to insulate walls, roofs, and floors.

These boards are a popular choice because of their ability to improve the energy efficiency of buildings. They are engineered with key characteristics such as:

High thermal resistance: Keeps your space warmer in the winter and cooler in the summer.

Moisture resistance: Certain rigid products such as XPS are closed-cell and therefore do not absorb water. (Some types of rigid boards are part open-cell, which means they will breathe to some degree, but will also absorb some moisture if they get wet),

Rigid insulation boards are typically made from foams like polystyrene, polyisocyanurate, and phenolic resin. Each type has unique properties suited for different applications.

Types of Rigid Insulation Boards

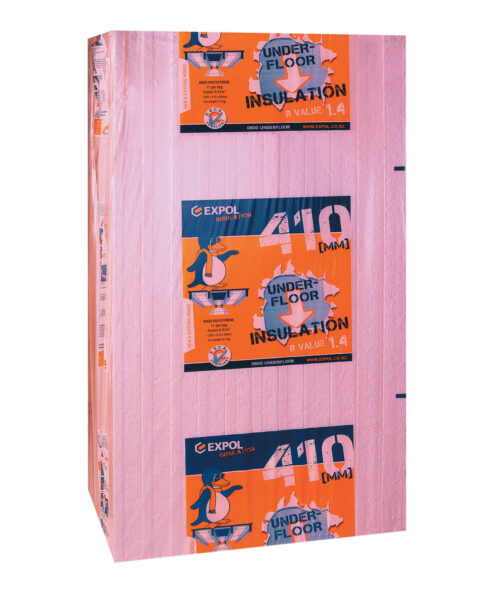

- Expanded Polystyrene (EPS): This lightweight, budget-friendly option excels in residential projects. Its versatility makes it suitable for walls, roofs, and underfloor applications. Extruded Polystyrene (XPS): Known for its exceptional strength and moisture resistance, XPS is ideal for below-grade applications like foundations and underfloor insulation. Effective as a vapour retarder, XPS doesn’t allow moisture vapour to pass through easily.

- Polyisocyanurate (PIR): Perfect for maximising thermal performance in limited spaces, offering one of the highest R-values per centre among rigid board insulations. PIR’s fire resistance properties make it suitablefor various applications, including walls and roofs, as well as moisture-sensitive environments like cold storage facilities.

- Phenolic Insulation: With exceptional thermal performance, this is a premium choice for walls, facades and roofs. Its thin design maximises space while providing superior fire protection and minimal smoke fumes in case of fire.

Benefits of Rigid Insulation Boards

Here are 6 ways rigid insulation boards contribute to a more comfortable and energy-efficient building:

- Comfort and Thermal Performance: High R-values reduce heat transfer, resulting in substantial energy savings and a consistent, comfortable indoor environment year-round.

- Moisture Resistance: The closed-cell structure of rigid board products such as XPS help to prevent moisture absorption.

- Durability and Stability: A rigid insulation panel maintains its shape and performance, ensuring long-lasting effectiveness and contributing to building integrity.

- Ease of Installation: Lightweight and easy to cut, these boards don’t shed irritating fibres, simplifying the installation process.

- Long-Term Cost Savings and Sustainability: While the initial cost may be higher, energy savings and material durability offer long-term financial benefits. This makes for a more sustainable building approach. Furthermore, thin rigid insulation boards can maximise floor space, enhancing property value.

- Versatility: Highly functional, rigid board insulation can reduce noise transmission when installed in internal walls.

Tips for Cutting Rigid Board Insulation

Follow these steps for a clean and straight cut:

- Measure the area where the board will be installed. Mark the measurements on the board with a pen or pencil. To avoid waste, double-check measurements before cutting.

- Choose the right tool.

- For panels 5cm thick or less, use a sharp utility knife with a long, sharp blade. Avoid short blades and cutting in a sawing motion.

- For panels over 5cm thick use a fine-toothed hand saw or a putty knife. Alternatively, you can score and snap thicker panels.

- Following the marked lines, use steady and even pressure with a knife, or cut slowly and steadily with a saw. Use a straightedge tool as a guide for straight cuts.

- Sand down any rough edges if necessary. This will help the boards fit snugly against each other, minimising gaps and optimising performance.

- Always wear safety glasses and gloves when cutting rigid board insulation.

FAQs on Rigid Insulation Boards

What are the recommended applications for rigid insulation boards?

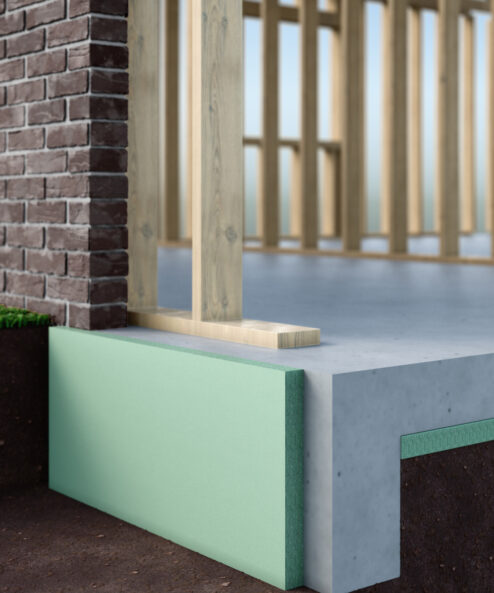

- Foundation, external, and internal wall insulation

- Roof insulation (sarking and underlay)

- Underfloor insulation

- Slab foundation insulation

- Slab edge insulation

- Basement insulation

- Car park insulation

- Garage door insulation

How do I determine the appropriate thickness of rigid insulation boards for my project?

- Climate region and building type

- Desired R-value (thermal resistance)

- Building codes and energy efficiency goals

Can rigid insulation boards be used in both residential and commercial buildings?

What is the expected lifespan of rigid insulation boards once installed?