Insulation Tips

When should I use Board Insulation?

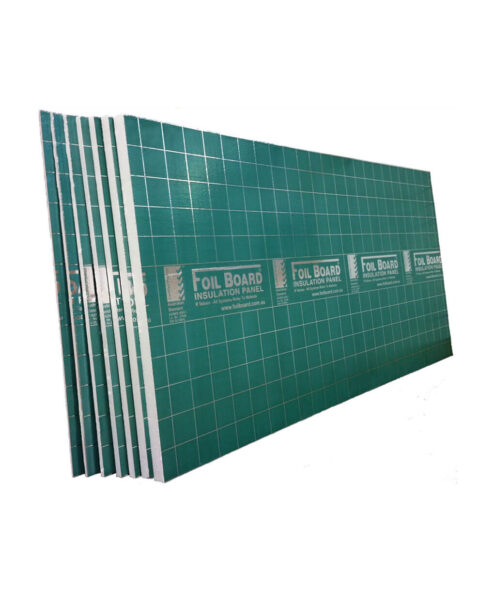

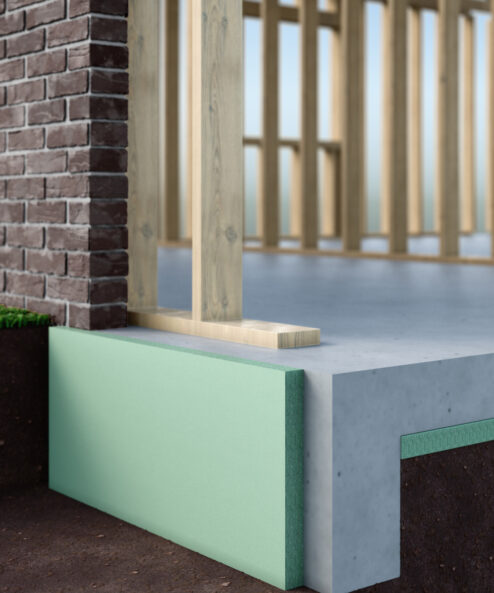

Insulation boards can be utilized in both commercial and residential settings and are a cost-effective alternative to fibreglass insulation. Rigid board insulation is available in varying thicknesses from 20mm to 100mm and standard sheet sizes of 1200mm x 2400mm. Board Insulation is designed to achieve high R-values with narrow thicknesses. Board insulation is moisture resistant, and can get wet, making it suitable for installation during the early construction phase. Typical uses for board insulation include; slab foundations, basements, exterior and internal wall insulation, and thermal barrier layer underneath radiant floor heating systems.

How Does Board Insulation Work?

Insulation Foam provides thermal resistance and reduces heat conductivity to keep your home warmer in winter and cooler in summer. So, if your board insulation is installed correctly it prevents heat conduction and thermal convection, which is the transfer of heat through one material to another, from a warmer to a cooler environment. Remember, don’t leave any gaps in your insulation, this will compromise the effectiveness of the insulation as air can freely pass through air gaps. Installing insulation in your home can lower your energy usage, increase energy savings and create a comfortable home to live in!

What materials are Board Insulation made of?

Insulation boards are rigid, durable and sturdy. There are a few materials that these boards are made of, below is a short description of common materials used.

Expanded Polystyrene (EPS) is a rigid cellular foam which is manufactured from petroleum and natural gas by-products. No ozone depleting CFCs and HFCs are involved in the manufacturing of this product. EPS is one of the cheapest board insulation materials and is 100% recyclable at selected REPSA collection centres across Australia

Extruded Polystyrene (XPS) is also a rigid foam that is manufactured using the extrusion process from a polystyrene polymer. XPS is shaped into sheets during the molten stage and once hardened can be further cut into required sizes etc. This product provides long term stable R-values and is moisture resistant.

Polyisocyanurate (PIR) is a closed cell, rigid foam insulation. It is used in both residential and commercial applications and can be used inthe roof, walls and underfloor areas. Due to its rigid structure it is easy to handle and can be easily fixed to most substrates. PIR board insulation has a high thermal value, due to its low thermal conductivity, giving buildings continued thermal efficiency throughout their life span.

What about the R-value of insulation boards?

The insulating properties of a material is measured by R-value, which provides an indication of the thermal resistance of a material. The higher the R-value the greater the insulating capabilities, and in rigid board insulation the thickness can be an indication of the R-value for that product. For example, PIRMAX has products starting from an R1.0 which is 20mm to R5.0 which is 10mm thick. If you need extra assistance with choosing R-values, feel free to contact us on 1300 729 639.

Installing Board Insulation

Insulation boards are clean, irritant-free and can be cut to any size. As the insulation foam is easy to cut this makes the installation process smooth and efficient, as hard to read areas can be fitted with cut insulation. Additionally, board insulation does not shed irritating fibres, making it easier to install and you don’t need to get ‘suited up’ beforehand. Also remember that due to the rigidity of the board the foam needs to be placed carefully around wall cables, electrical outlets etc. Overall, board insulation makes a great DIY project for the handy man!